People also read

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Created on : 24-07-20242024 by Asset-Eyes Subject Matter Expert HVAC System

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Industrial fans are as varied in their construction as they are in their applications. There are only two basic types of industrial fans: Axial Fans and Centrifugal fans. The other fans and blowers fall under various classifications like Industrial Blowers, Industrial Ventilation Fans, Exhaust Blowers, Industrial Exhaust Fans, hvac fans and blowers, and many others terms are used to define a Centrifugal Fan or an Axial Fan.

Before getting into the understanding of Axial and Centrifugal fans, we often use the word Fans and Blowers synonymously. Are they one and the same? Let us first discuss the difference between the term Fan and Blower

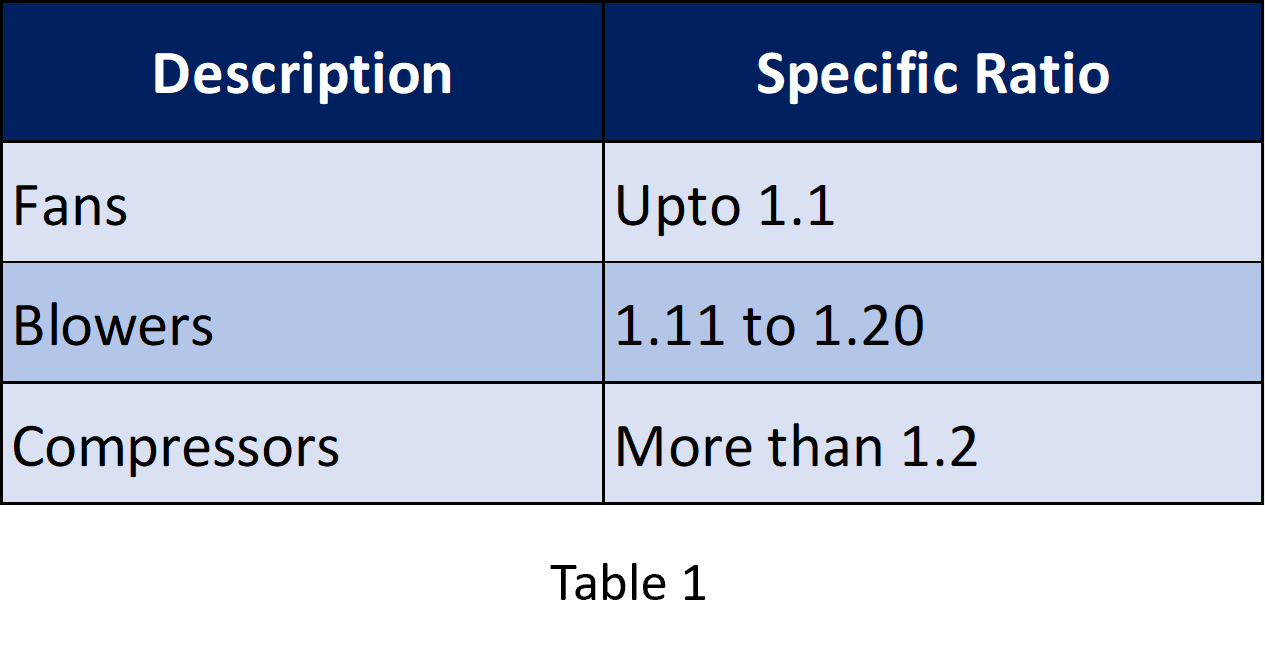

Fans, blowers and compressors are differentiated by the method used to move the air, and by the system pressure they must operate. As per American Society of Mechanical Engineers (ASME) the specific ratio (i.e) the ratio of the discharge pressure over the suction pressure is used for defining or differentiating the fans, blowers and compressors. The following tabular column explains it better.

It is self-explanatory from the above tabular column that the term Fans and Blowers are not one and the same.

Axial fans got their name for the way the fan blades operate. Rotating around an axis and thereby pushing air out in a way that’s parallel to the axis.The major types of axial flow fans are: Tube axial, vane axial and propeller

Tube Axial Fans

They have a wheel inside a cylindrical housing, with close clearance between blade and housing to improve airflow efficiency. The wheel turn faster than propeller fans. The efficiency of the fan goes up to 65%.

Vane Axial Fans

They are like tube axials, but with addition of guide vanes that improve efficiency by directing and straightening the flow. As a result, they have a higher static pressure. Vane axial fans are the most efficient in the axial fans family.

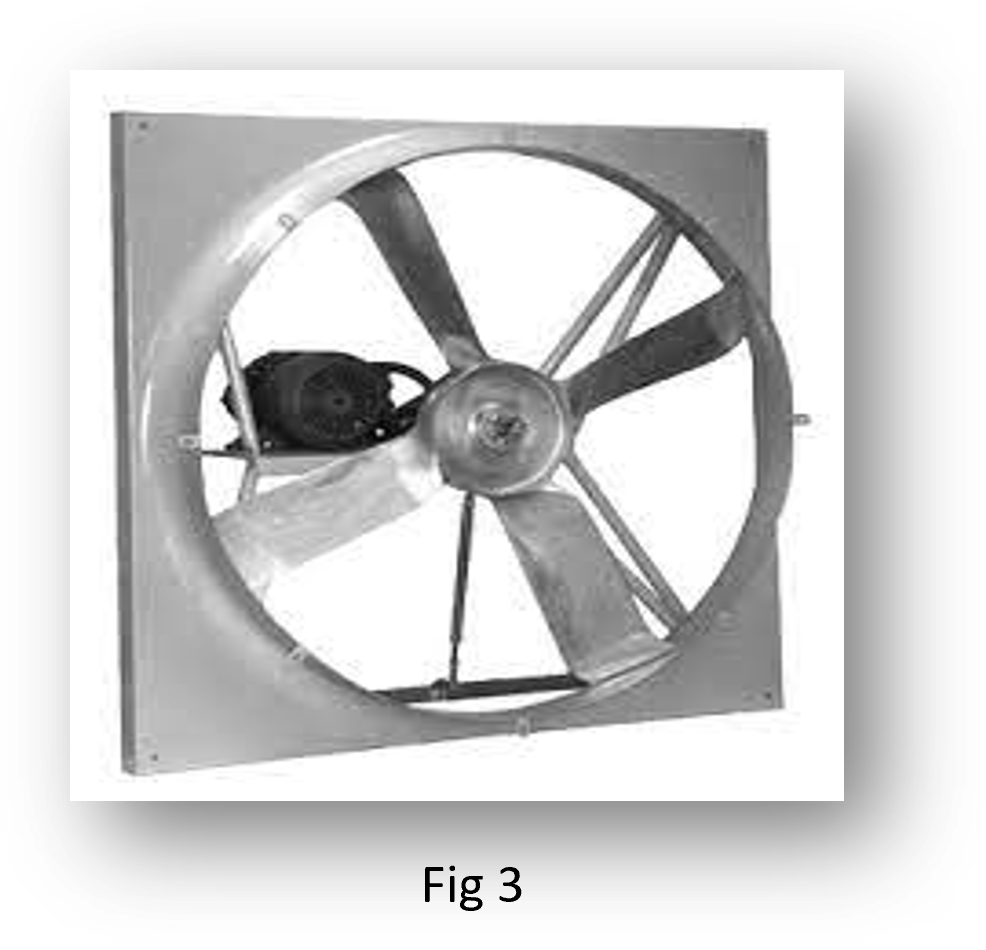

Propeller Fans

They usually run at low speeds and at moderate temperatures. They experience a large change in airflow with small changes in static pressure. They handle large volumes of air at low pressure or free delivery. Propeller fans are often used indoors as exhaust fans. Outdoor applications include air-cooled condensers and cooling towers.

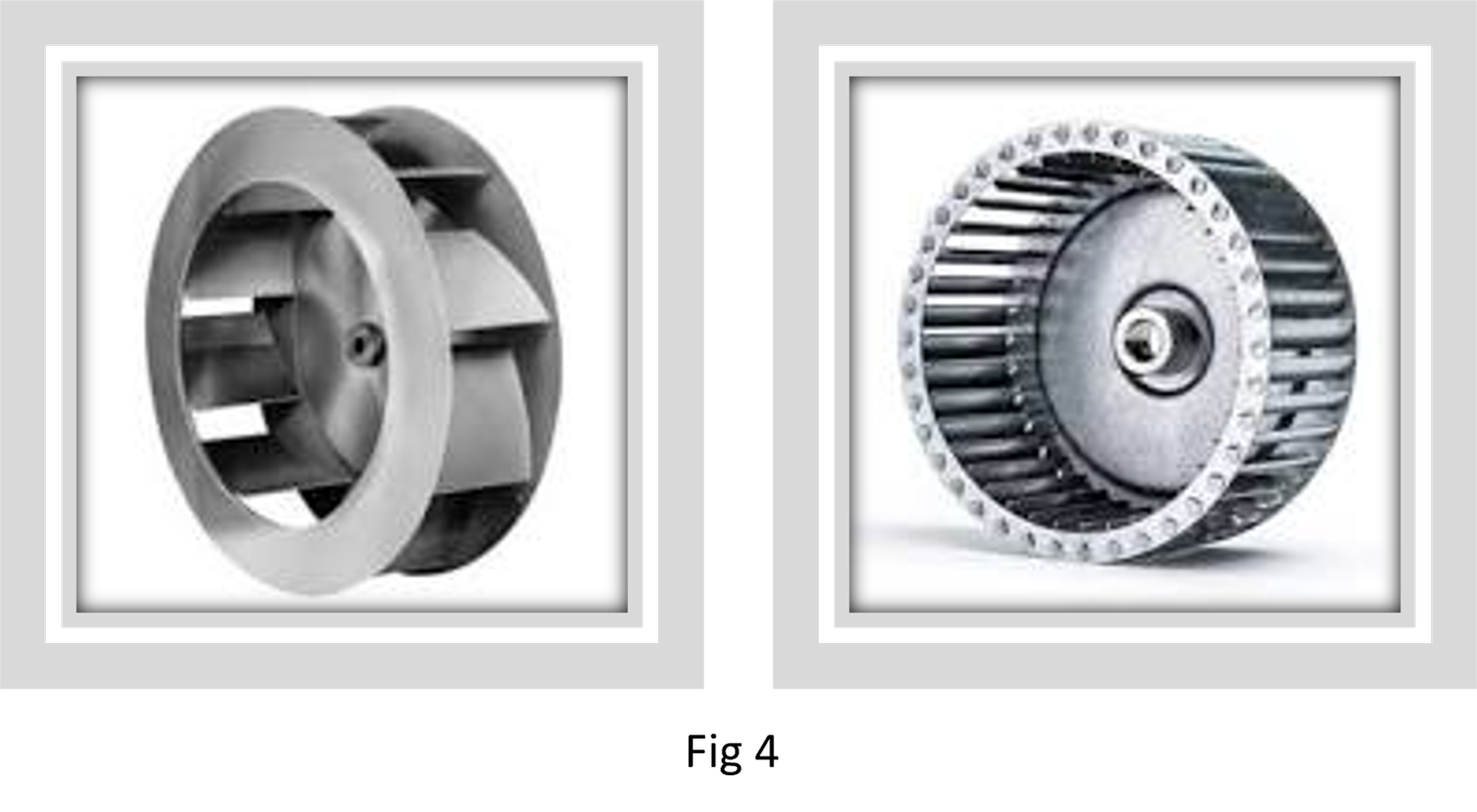

It extract air at right angles to the intake of the fan, and spin the air outwards to the outlet by deflection and centrifugal force. The impeller rotates, ausing air to enter the fan near the shaft and move perpendicularly from the shaft to the opening in the fan casing. airflow changes direction twice - once when entering and second when leaving.

These fans are classified based on the construction of the impeller. Broadly, it is divided into Forward curve and Backward curve.

Which Is Best For Your Application?

The best way to decide which fan is right for your application is to take a deeper look at some of the key strengths and weaknesses of each.

Pressure

When we talk about fan pressure, we’re referring to the type of air that it creates in a select area. Axial fans create low-pressure air, as the design of such fans allows these devices to distribute air somewhat evenly in a defined area.

Radial fans, conversely, generate high-pressure air. In other words, they’ll create a steady flow of air that can be used to target a concentrated area.

Volume

Axial fans distribute high volumes of air, just not high-pressure amounts of air. As stated previously, this makes them great for areas where large amounts of air displacement are necessary.

While radial fans generate high-pressure air, they don’t generate it in large volumes.

Noise

Axial fans are noisier than radial fans, which can be a factor in certain industrial environments. We need to be careful while selecting and taking the opinion of the expert will help to narrow down the selection.

Maintenance

Axial fans tend to operate with a great deal of turbulence, which puts an increased amount of wear and tear on the device. This can result in more maintenance or earlier replacement than radial fans over time.

Size

Though many manufacturers will make fans based on consumer request, axial fans are more complex and portable than radial ones. Radial fans that are installed in industrial environments are typically very heavy, large and there to stay once they’re placed.

Fluid Handled

Since the fluid handled by the axial fan passes parallel to the shaft, the fluid will be in contact with the motor (in case of direct driven) or will be in contact with the belt (in case of Belt driven), the dame of motor or the belt is inevitable, if the fluid handled is abrasive in nature.

For such fluids, centrifugal fan will be a better option as none of the drive components (Such as Motor, Belt, Pulley, Bearing etc) will not be in contact with the fluid handled.

Energy

Generally, backward curve centrifugal fans are much efficient than the axial fans. However, if the required static pressure is lesser than certain levels, the axil fans will prove to be a better option. A proper evaluation required by a technical expert before concluding the type of fan.

Conclusion

Understanding the difference between axial and radial fans is critical in making the right choice for your application. Each type of fan has its fair share of benefits and drawbacks. You may find that a combination of each might suit your application the best.

Online Vs Offline Vibration analysis in HVAC Systems A forethought before investing.

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

To answer “Where to choose What”, we need a thorough audit of the available equipment and evaluate their technical feasibility.

Learn More

Centrifugal Fan and Axial Fan ; which is best for your application?

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Industrial fans are as varied in their construction as they are in their applications. There are only two basic types of industrial fans: Axial Fans and Centrifugal fans. The other fans and blowers fall under various classifications like Industrial Blowers, Industrial Ventilation Fans, Exhaust Blowers, Industrial Exhaust Fans, hvac fans and blowers, and many others terms are used to define a Centrifugal Fan or an Axial Fan.

Learn More

Is EC fan really a One Stop Solution for the reduction of Carbon Footprint?

Created on : 24-07-20242024 by Asset-Eyes Subject Matter Expert HVAC System

Of late lot many discussions are happening around on reducing the carbon footprint. In a typical industrial scenario, be it Manufacturing or a process Industry, Centrifugal equipments like Fans, Pumps and compressors (Centrifugal) are energy guzzlers.

Learn More

The Role of Duct Design in Efficient HVAC Systems

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Who is responsible for the energy efficiency of a centrifugal fan which are used in HVAC and Industrial Ventilation system; whether it Fan or the man who designed it? The answer “Neither of the two” is true to a very large extent. Such is the importance of duct and in turn in the well-thought-out duct design in a HVAC system. How?

Learn More

Considerations while selecting a Centrifugal Fan in a HVAC system

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Centrifugal fans are the most versatile air moving equipment. The housing (volute) of the centrifugal fan accelerates the air and changes the direction of the airflow twice, that is 90⁰ before leaving the volute / housing. These fans are relatively quite and reliable. If selected properly, these centrifugal fans are highly energy efficient. The following paragraphs discuss about the considerations to be made while selecting a centrifugal fan for your HVAC application.

Learn More

Is a fan serving its purpose in an HVAC System always Energy Efficient?

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

It is often said in plants that a HVAC system which is delivering the desired temperature and Relative Humidity is working fine. Is it a complete statement? Although the desired parameters of HVAC system are met, the plant managers do have a complaint that the specific energy consumption (That is Electrical energy consumed per product produced) is higher than the other plants of similar size and facility. The following paragraphs are about one such experience we had while auditing a plant.

Learn More