People also read

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Created on : 24-07-20242024 by Asset-Eyes Subject Matter Expert HVAC System

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Centrifugal fans are the most versatile air moving equipment. The housing (volute) of the centrifugal fan accelerates the air and changes the direction of the airflow twice, that is 90⁰ before leaving the volute / housing. These fans are relatively quite and reliable. If selected properly, these centrifugal fans are highly energy efficient. The following paragraphs discuss about the considerations to be made while selecting a centrifugal fan for your HVAC application.

Radial: These are suitable for high pressure and medium airflow requirements. Typical HVAC systems fall under this category. Even shop ventilation systems, these types of radial fans are suitable and energy efficient.

Forward curve: These are medium pressure, high airflow fans that can be used in both clean airs, ventilating and exhaust applications. Having said, when compared to backward curve (Refer below), these types of impellers have lesser mechanical efficiency.

It can be seen from the figure 1 that the orientation of the impeller vanes is along the direction of rotation.

Backward Curve: These are high-pressure, high flow, high efficiency fans. Power reduces as flow increases over the most efficient area of the system. Typical suitable for Air conditioning and ventilation systems.

It can inferred from Fig 2 that the orientation of impeller vanes is opposite to the direction of rotation.

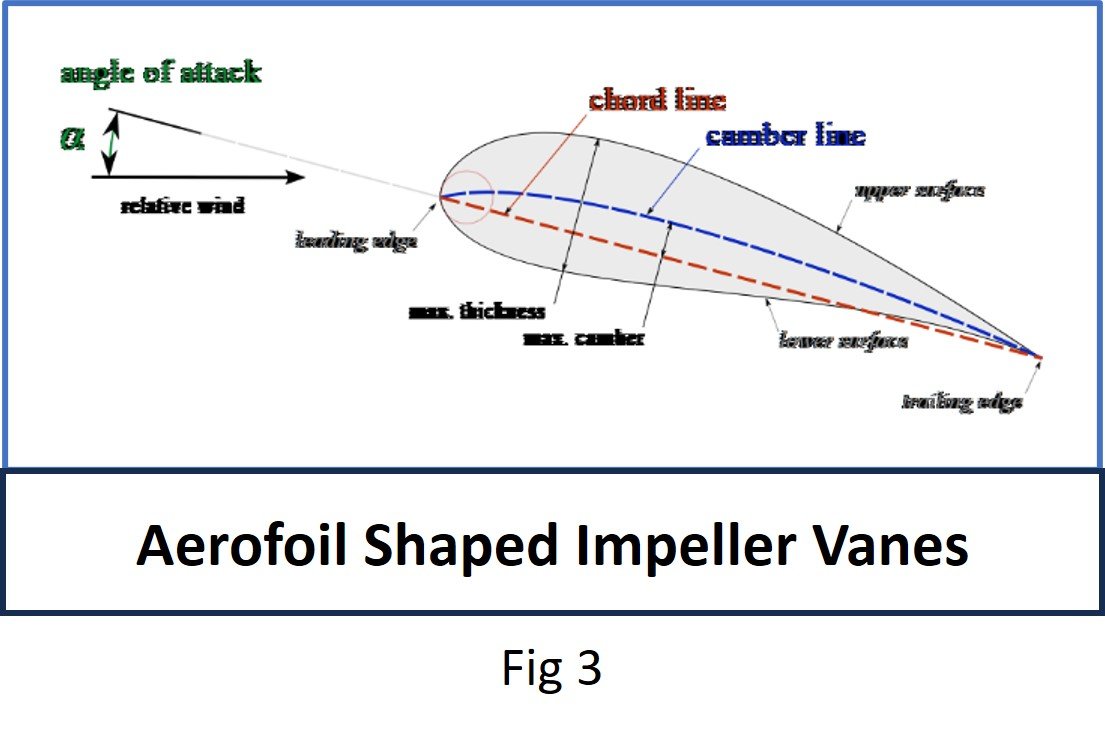

Aerofoil: These are the highest efficiency fans, best in clean air applications. Please refer the shape of the vane, which looks like a Rain drop

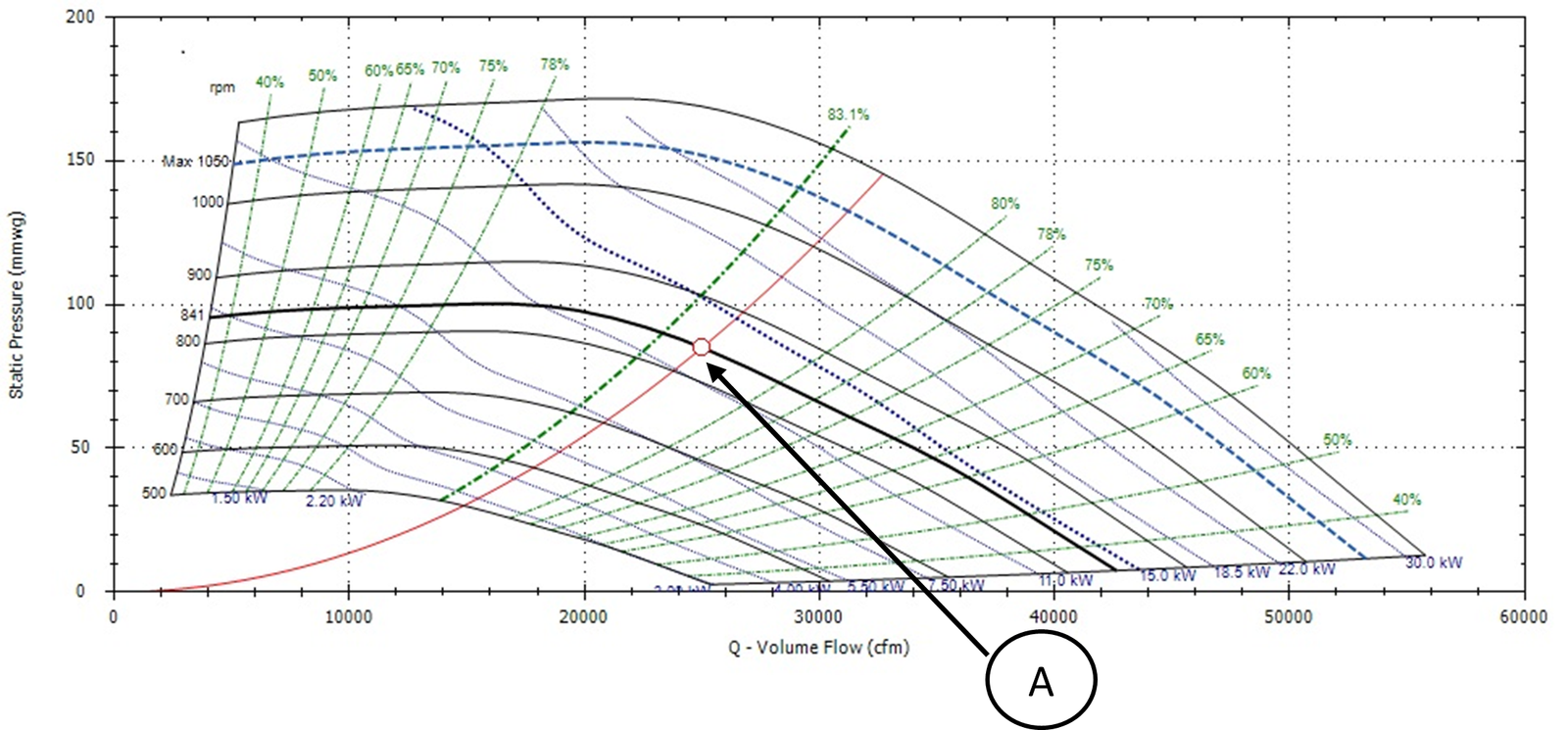

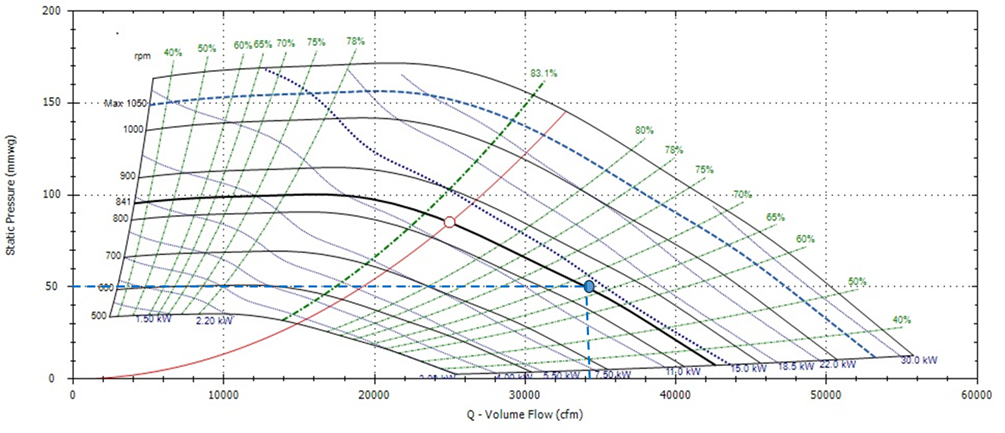

To choose an appropriate centrifugal fan we need to know the required airflow for the process and the static pressure required. In general, arriving at the required air flow will not create much of a concern, where arriving at the static pressure is where concern arises. Arriving at optimal static pressure is one of the influencing factors in selecting an efficient centrifugal fan.

How to determine the optimum static pressure?

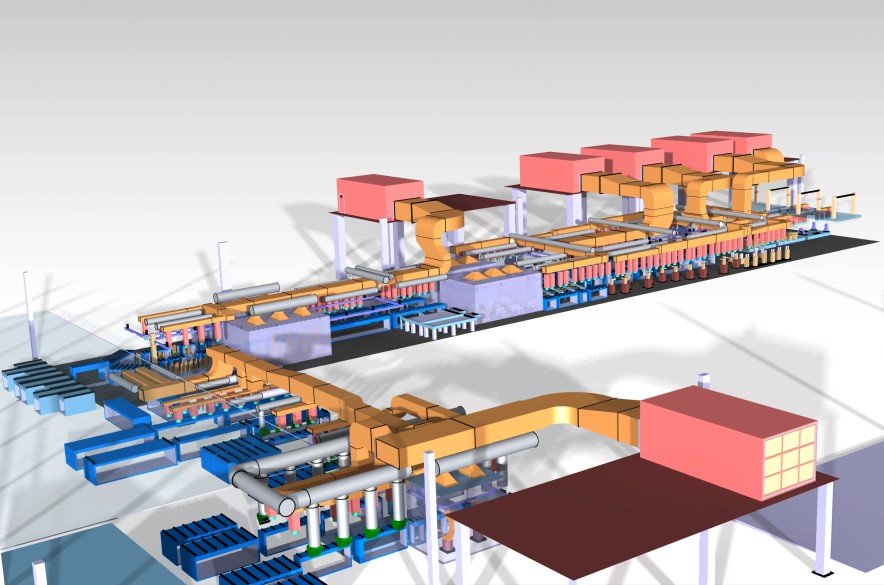

Before selecting the centrifugal fan, we need to decide on the layout of the HVAC system. Based on the airflow to be distributed to various places in a building / shop floor, we need to arrive at the layout of duct. It is important not to alter much in the ducting layout once the fans are selected and manufactured. Drastic changes in ducting layout will affect the required static pressure to a greater extent. Change in static pressure will alter the operating point, which means change in airflow (either increases or decreases) and the static efficiency of the fan.

We designers of the HVAC system generally have a tendency of adding factor of factor of safety to the calculated parameter of the fan (Flowrate of Air & Static pressure). While arriving at the static pressure, it is important not to add much of factor of safety. If suppose, the calculated static pressure of 45mm of Aqua and if we add a 30% factor of safety, the static pressure would be 59mm of Aqua. In reality (Actual after installation) if the static pressure is around 40mm of Aqua, the fan will try to give more airflow and at the same time, the efficiency of the fan will come down, which will result in increase in power than expected.

Hence key to success in arriving at optimum static pressure are.

Corrosive Environment: In wet, humid environments, a stainless-steel blower is recommended, preferably with a stainless wash-duty motor.

Hazardous Environment: Consider a non-sparking blower, such as a radial or high-pressure blower, with an explosion-proof motor.

Clean Air: Consider a forward curve, backward inclined or airfoil blower for increased efficiency.

Lightly Dusty Air: Consider a radial or high-pressure blower. For very light, non-abrasive dusts, a backward inclined blower is acceptable.

Corrosive: In wet, humid, corrosive environments, you should opt for a stainless steel blower, preferably with a stainless wash-duty motor.

Combustible: If there's combustible dust or particulate in the air, opt for a non-sparking blower (Example paint booth application), such as a radial or high-pressure blower with an explosion-proof motor.

Air Temperatures: Use belt drive units with steel wheels in higher temperatures. If temperatures climb above 120°C, consider an industrial blower with a heat slinger (For dissipates heat from the fan shaft).

The drive arrangement names use these abbreviations:

SW = Single Width

DW = Double Width

SI = Single Inlet

DI = Double Inlet

In total 10 arrangements can be made with major classification of SISW and DIDW. Since the intent of the article is not to elaborate on the arrangement, it is not mentioned.

Inspection And Testing of Centrifugal Fans

It is important to carry out the following tests before purchasing the centrifugal fan.

Mounting of Centrifugal Fan

As most of the centrifugal fans in the Air Handling Units (AHUs) are mounted over a metal structure at a height or mounted on a concrete structure at a height, the isolation vibration plays an important role. It is advisable to mount the fan fans over a rigid metal frame with Vibration Isolators with spring. This will have a better life when compared to conventional rubber mounts.

The optimal selection of Centrifugal fan plays a major role in deciding a HVAC system to deliver the required process parameters like temperature and Humidity and the operational efficiency. Poor selection of Centrifugal fan might satisfy the process parameters, but the cost of running or the “Life Cycle Cost” of the plant and capital expenses might go high. Hence a detailed analysis and a meticulous selection of Centrifugal fan will help in reducing the Life Cycle Cost of the HVAC system.

Online Vs Offline Vibration analysis in HVAC Systems A forethought before investing.

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

To answer “Where to choose What”, we need a thorough audit of the available equipment and evaluate their technical feasibility.

Learn More

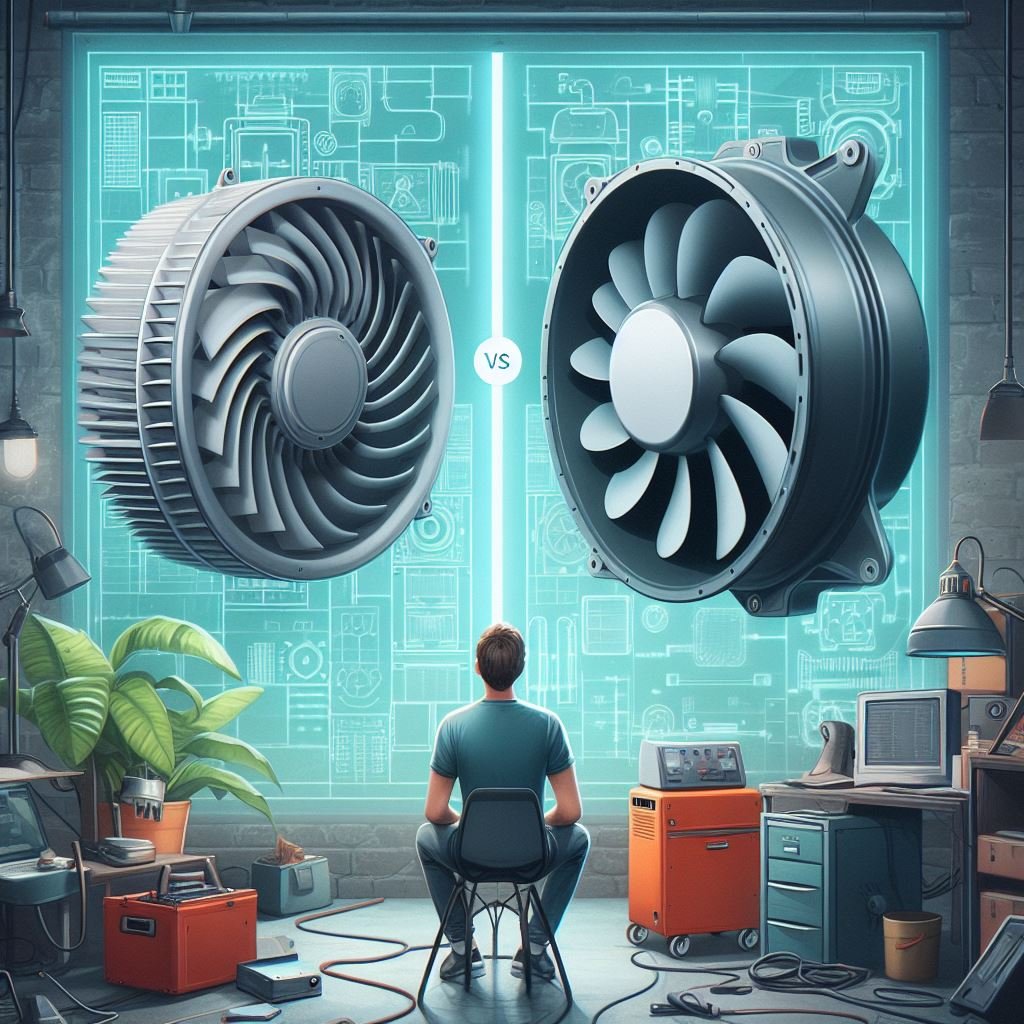

Centrifugal Fan and Axial Fan ; which is best for your application?

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Industrial fans are as varied in their construction as they are in their applications. There are only two basic types of industrial fans: Axial Fans and Centrifugal fans. The other fans and blowers fall under various classifications like Industrial Blowers, Industrial Ventilation Fans, Exhaust Blowers, Industrial Exhaust Fans, hvac fans and blowers, and many others terms are used to define a Centrifugal Fan or an Axial Fan.

Learn More

Is EC fan really a One Stop Solution for the reduction of Carbon Footprint?

Created on : 24-07-20242024 by Asset-Eyes Subject Matter Expert HVAC System

Of late lot many discussions are happening around on reducing the carbon footprint. In a typical industrial scenario, be it Manufacturing or a process Industry, Centrifugal equipments like Fans, Pumps and compressors (Centrifugal) are energy guzzlers.

Learn More

The Role of Duct Design in Efficient HVAC Systems

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Who is responsible for the energy efficiency of a centrifugal fan which are used in HVAC and Industrial Ventilation system; whether it Fan or the man who designed it? The answer “Neither of the two” is true to a very large extent. Such is the importance of duct and in turn in the well-thought-out duct design in a HVAC system. How?

Learn More

Considerations while selecting a Centrifugal Fan in a HVAC system

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

Centrifugal fans are the most versatile air moving equipment. The housing (volute) of the centrifugal fan accelerates the air and changes the direction of the airflow twice, that is 90⁰ before leaving the volute / housing. These fans are relatively quite and reliable. If selected properly, these centrifugal fans are highly energy efficient. The following paragraphs discuss about the considerations to be made while selecting a centrifugal fan for your HVAC application.

Learn More

Is a fan serving its purpose in an HVAC System always Energy Efficient?

Created on : 24-07-20242024 by Author: Subject Matter Expert & Consultant in HVAC Systems at Asset-Eyes Infomatics

It is often said in plants that a HVAC system which is delivering the desired temperature and Relative Humidity is working fine. Is it a complete statement? Although the desired parameters of HVAC system are met, the plant managers do have a complaint that the specific energy consumption (That is Electrical energy consumed per product produced) is higher than the other plants of similar size and facility. The following paragraphs are about one such experience we had while auditing a plant.

Learn More